| A6061-T1 (the most suitable material for industrial and residential construction, improves performance efficiency, and solves the environmental problems that have been sprung from using conventional Formwork system.) |

|

|

|

| Compared to the existing Euro-form(made of timber and steel), it has more accuracy in a horizontal and vertical structure. Because of the excellent quality of the panel and connection part, it is easy to do insertion work. Therefore, total construction quality and structure performance will be improved. | |

| Because of the easy way of construction, we don’t need skilled workers to build. It means the reduction of labor costs. Also, it prevents from arising of post-construction cost with its high quality. | |

| With the large size of basic panel and simple product formation, the assembling and disassembling period is reduced. | |

| Because of the wider spaces between one support and the other one support compared to the way of existing construction, it has more wide spaces in the job site than the existing one. Also, it is more convenient to handle units with its lightweight. | |

|

|

| Compared to the existing Euro-form(made of timber and steel), it has more accuracy in a horizontal and vertical structure. Because of the excellent quality of the panel and connection part, it is easy to do insertion work. Therefore, total construction quality and structure performance will be improved. | |

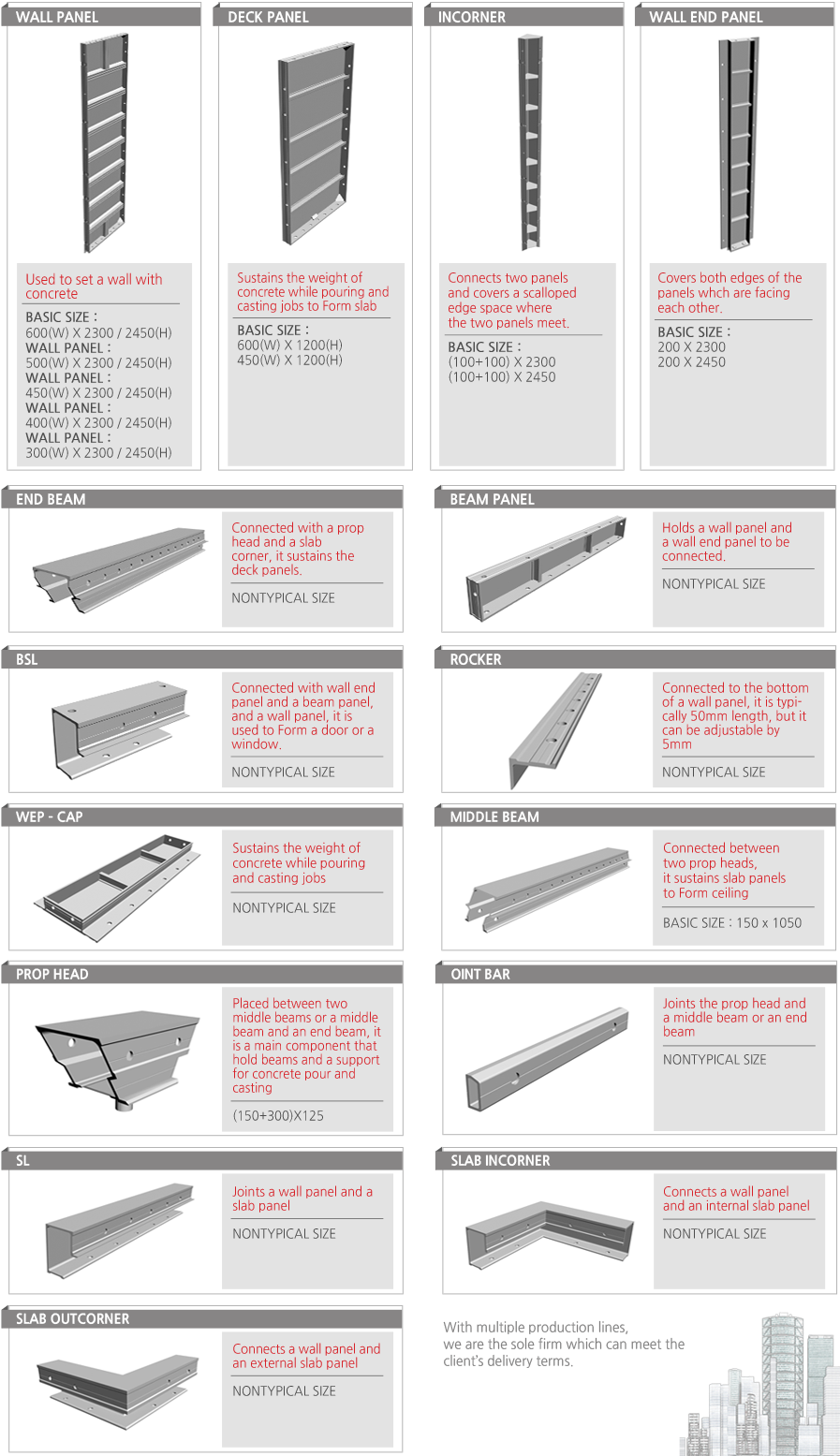

Aluminum Wall & Slab deck

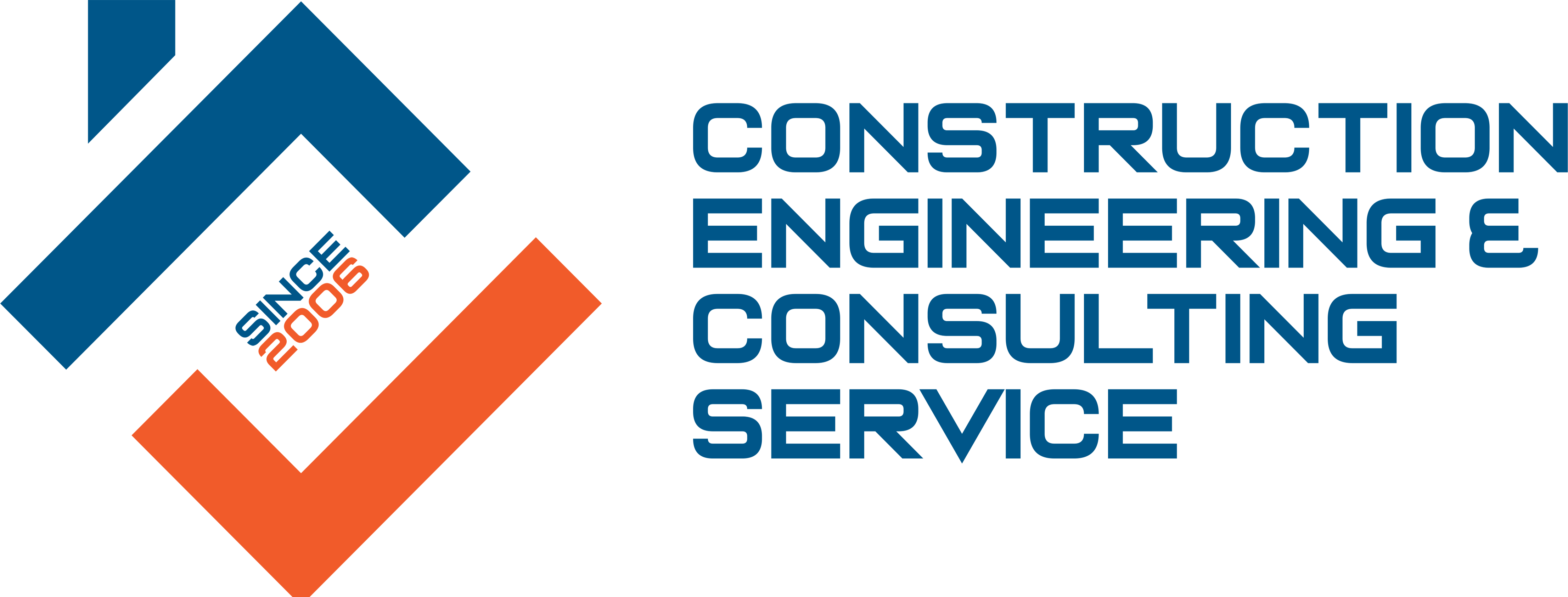

A broad range of components is essential to build any type of building.

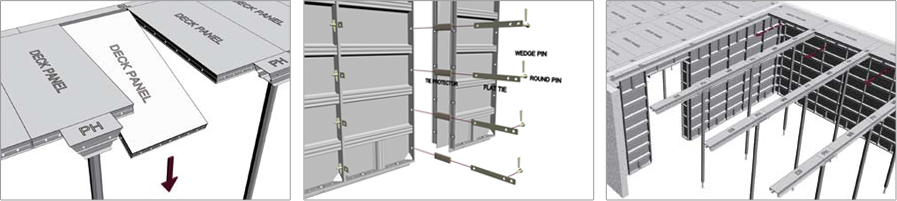

ASSEMBLING & DISASSEMBLING

ALUMINUM SUPPORT

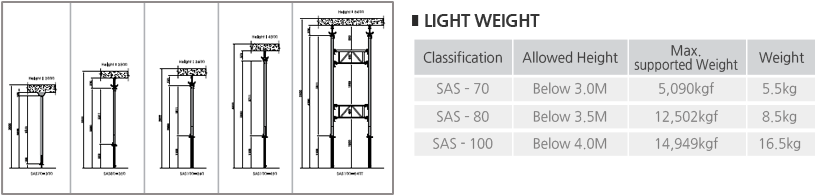

Lighter, Stronger. We are making relentless efforts to provide a better solution for your successful project.The Aluminum Support is lighter than steel support and it withstands more weights.

The Aluminum Support is adjustable to each individual construction site condition and it is available in different lengths from 1.8 meters to 5.5 meters. We have three types available in SAS 70, 80, and 100 and it can be used for a wide range of heights with single or couple of support frames.

QUALITY IMPROVEMENT

Aluminum support is lighter than steel support. For instance, Aluminum support SAS70 which weights 5.5kg is lighter than Steel support v2 which weights 15kg but it can resist the same pressure.

STRONG

In the case of SAS70, it can resist more 500kg compared to V2. (Maximum supported weight of SAS70: 5090kg, Maximum supported weights of V2: 4527 kg)

ADJUSTABLE

Aluminum support is adjustable to each individual site conditions and it is available in different lengths from 1.8 meters to 5.5 meters. We have three types available in SAS70, 80, and 100 and it can be used for a wide range of heights with a single or couple of support frames.

- SAS-70 is used in the building which has a lower height than 3 meters and it can support a maximum of 5 tons.

- SAS-80 is used in the building which has a lower height than 3.5 meters and it can support a maximum of 12.5 tons.

- SAS-100 is used in the building which has a lower height than 4 meters and it can support a maximum of 15 tons.

In case that the allowed weight is used as the single supporting method, it means the weight applying the safety rate 3.

In case that it is used over the allowed height, a separate structure is calculated.

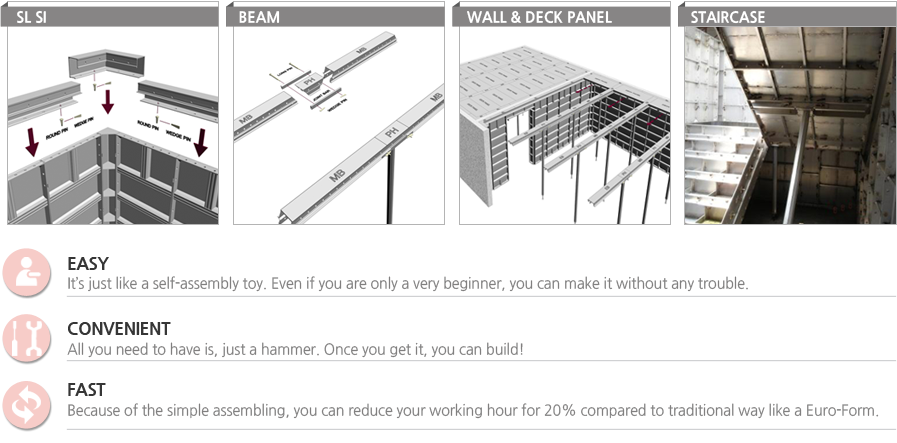

HI-TECH FORM

| Hi-tech Form applies a drop-down system to aluminum Form, which is system Form to solve the noise problem in installing and disassembling it, which is the demerit of aluminum Form. Because of its reduced noise compared to the former one, it helps constructors to prevent from receiving civil complaints while doing their job in the downtown area. That means your construction work in the downtown area would be much easier. | ||||||||||||||

|

||||||||||||||